Looking good.

There‘s no harm in showing excellent surface quality!

LIGNATUR elements are manufactured according to the principle of «shell equals finish». Neat knotholes are fixed by a special gluing method. We glaze the finished elements in the factory on request or apply sunlight protection to effectively reduce the natural darkening of the timber. Ambitious design ideas are realised with simple bearing details and integrated trimmer.

Explanation videos on aesthetics

The surfaces of the elements are already so good-looking that they have finishing quality. In addition, plain bearing and connection details make for beautiful component transitions. Coatings and glazes can add a visually aesthetic extra to the element.

In the films, our consultants explain how it's done with LIGNATUR.

Would you like to learn more? Contact our team.

Planing

Excellent surface properties permit designs based on the principle of «shell equals finish».

The neat knotholes, fixed with special gluing technique, won´t break with planing. The result is a natural surface without unaesthetic mended knotholes.

![[Translate to Englisch:] Oberflächenqualität [Translate to Englisch:] Oberflächenqualität](/fileadmin/ablage/bilder/produkt/aesthetik/oberflaechenqualitaet-700.jpg)

Surface quality

A – LIGNATUR: for visible ceilings with box elements (LKE) in residential buildings

Surface neatly planed, neat knotholes are fixed by special gluing method, occasional resin pockets mended, no colour differences from blue stain or red discolouration.

We sand the element underside of LIGNATUR box elements for you up to a height of 240mm (As – LIGNATUR).

N – LIGNATUR: for visible ceilings in residential, school and office buildings

Surface neatly planed, knotholes are fixed by special gluing method, occasional dry cracks, occasional dry resin pockets, large resin pockets mended, almost no colour differences from blue stain or red discolouration.

G – LIGNATUR: for visible ceilings of sports halls, public and commercial buildings

Surface neatly planed, larger knots, knotholes are fixed by special gluing method, larger resin pockets mended, longitudinal cracks and colour differences permissible to a limited degree.

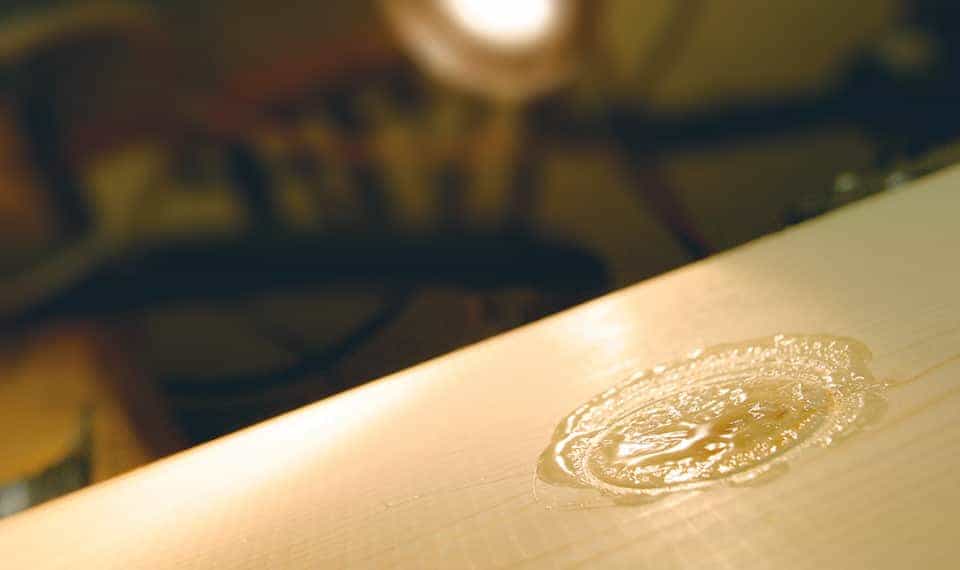

Glaze

Two thirds of the elements leave our production area untreated and keep their natural finish. On request we treat the finished elements here in our factory. If we glaze the elements white, the fine shrinkage cracks in the knot become invisible, as a result of the gluing method.

1 natural spruce

2 sunlight protection

3 white glazing

Finishing by brushing

The natural product wood itself already has an unmistakable charm. The newly available LIGNATUR elements with the character of old wood give the freshly renovated property with its rustic ambience a very special touch.

Each tree tells a story that has grown over the years. Each growth ring is unique in hardness, width and colour. The liveliness of wood has always fascinated people. Refinement by brushing brings this uniqueness to the fore.

This surface not only has an exciting look – it is also more resistant. This is why brushed wood is also an attractive choice for floors. Shown here is the upper cover lamella in steamed spruce.

![[Translate to Englisch:] LKE gebürstet und gedämpft [Translate to Englisch:] LKE gebürstet und gedämpft](/fileadmin/ablage/bilder/messen/veredelung_durch_buersten.jpg)